Customer Case Study: SUNJEESPOM Helps Fujian Building Materials Group Build a 3M TPY High-Quality Aggregate Production Line

1. Client Background & Challenges

A leading building materials supplier in Fujian Province, China, our client operates businesses in ready-mix concrete, dry-mix mortar, and various building materials. Facing strict government controls on natural sand mining and shifting market demands, the group decided to invest in a new 3 million tons per year high-quality manufactured sand and aggregate production line. This would meet the stringent demands of their own batching plants and the external market for premium aggregates.

Key Challenges:

Extremely Abrasive Feed Material: The primary raw material is local basalt, known for its high hardness, toughness, and high silica content. This posed a top-tier challenge to the wear resistance, impact resistance, and crushing efficiency of the equipment. Controlling wear part costs was critical to profitability.

Stringent Product Specifications: Their concrete plants and specific engineering projects demanded aggregates with excellent particle shape, strict grading, and low powder content. Low flakiness index and cubical grains were essential for achieving high concrete strength and workability.

High Capacity Requirement: The line required continuous, stable operation with an hourly output exceeding 500 tons. High automation was necessary to minimize operational costs and downtime.

Stringent Environmental Standards: Located in a developed coastal economic zone, the plant had to comply with strict environmental regulations for dust and noise pollution.

2. SUNJEESPOM Solution & Core Equipment Configuration

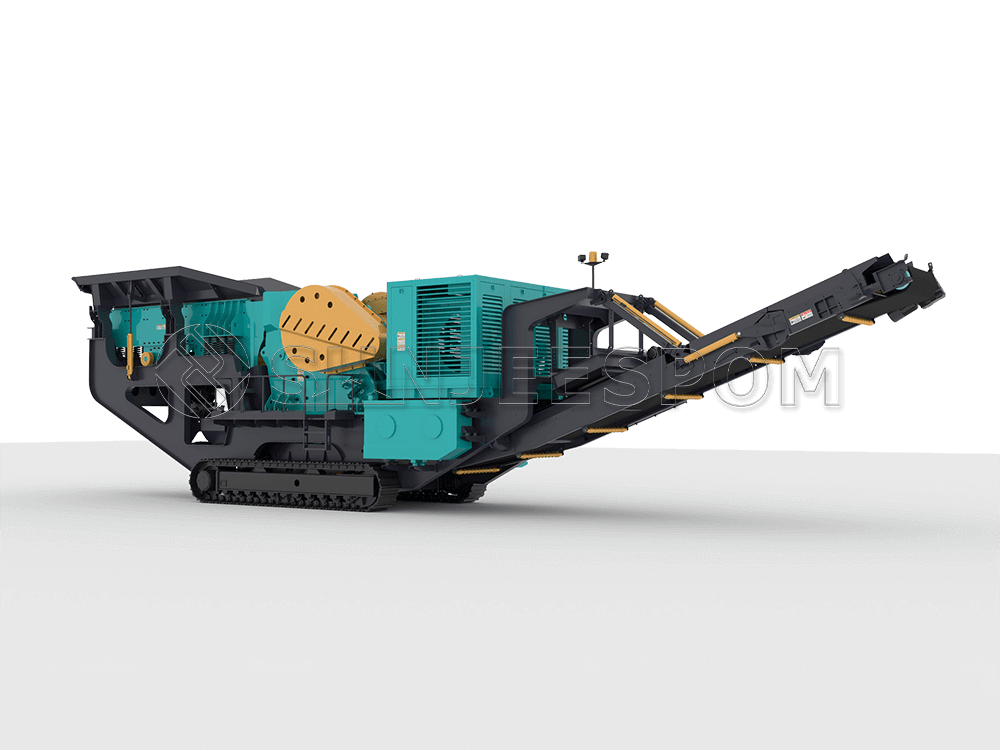

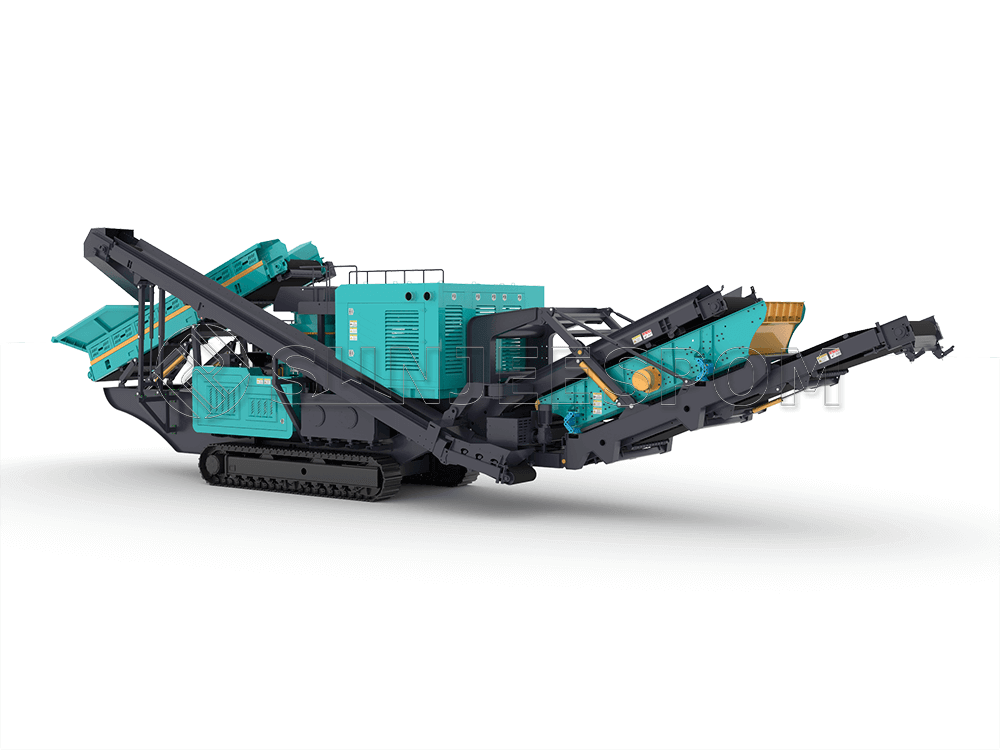

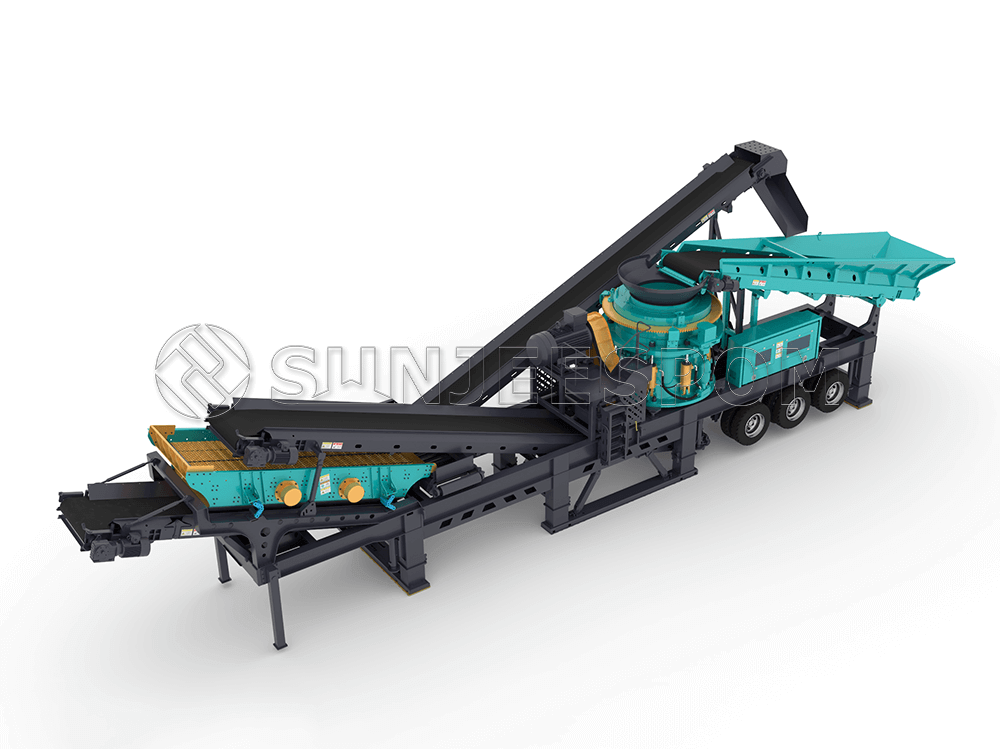

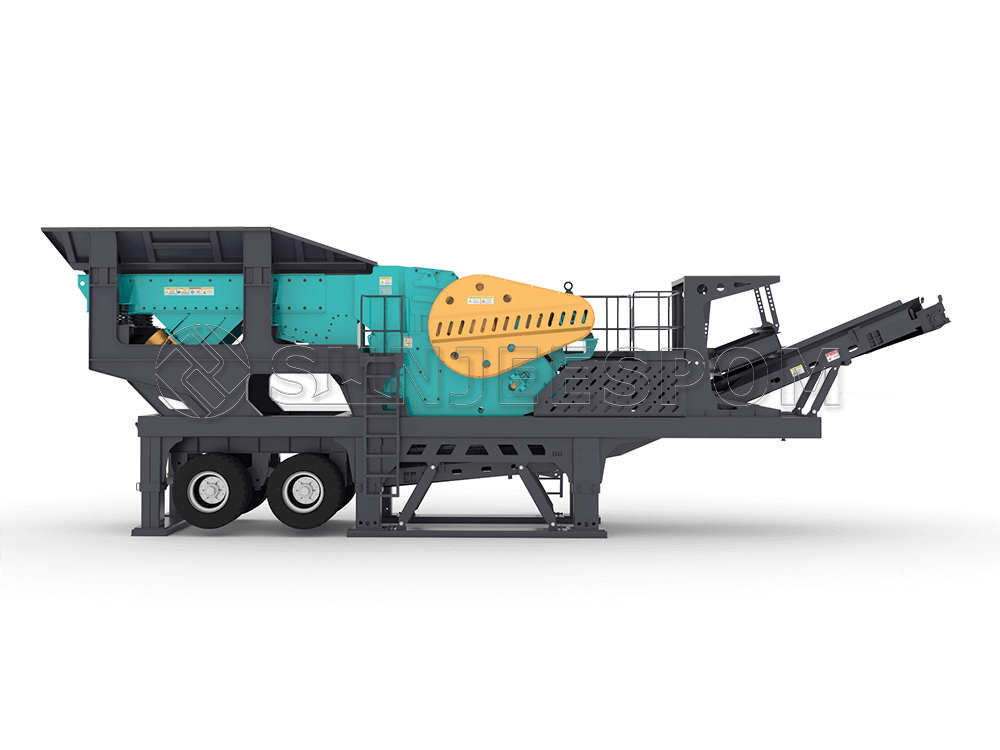

To conquer the challenge of processing highly abrasive basalt, SUNJEESPOM's engineering team conducted in-depth material analysis and (working condition simulation), providing a tailor-made, ultra-wear-resistant, efficient, and eco-friendly solution centered on "laminating crushing" and "impact crushing".

Core Equipment List:

Main Crushing Stage: SUNJEESPOM SH Single-Cylinder Hydraulic Cone Crushers (Multiple Units) - Specially Optimized for Basalt

Secondary Crushing & Sand Making Stage: SUNJEESPOM VSI Series High-Efficiency Centrifugal Impact Crushers (Multiple Units) - Superior Wear Protection Configuration

Screening Stage: SUNJEESPOM Multi-Layer High-Frequency Vibrating Screens (Multiple Units)

Auxiliary Systems: Complete belt conveyor system, centralized electrical control system, high-efficiency pulse baghouse dust removal system, and intelligent spray dust suppression system.

Why SUNJEESPOM's Solution Stands Out:

Main Crushing Core – Cone Crusher Built for Hard Rock: To handle the extremely hard and abrasive basalt, we deployed our specially configured SH Single-Cylinder Hydraulic Cone Crusher. Featuring super high manganese steel wear parts (mantle, concave) and an optimized crushing chamber design, it achieves efficient laminating crushing, reducing feed material below 50mm. It offers high output with low energy consumption and produces aggregates with superior particle shape and a very low flakiness index, significantly increasing the value of the end products. The advanced hydraulic system enables fully automatic discharge opening adjustment and iron passing protection, ensuring exceptional stability and safety for long-term operation under the most demanding conditions.

Sand Making Core – High wear-resistant sand making machine: The SUNJEESPOM VSI sand making machine was equipped with a premium wear package, including and embedded wear blocks, to effortlessly transform small basalt rocks into high-quality 0-5mm manufactured sand. The optimized rotor design and material flow produce rounded, well-graded sand with an adjustable fineness modulus, fully meeting the Zone II standard for concrete and special engineering applications.

Precise Screening – Multi-Layer Vibrating Screens: Multiple SUNJEESPOM 3-layer heavy-duty vibrating screens ensure precise classification of crushed material, separating it into various finished product specifications like 0-5mm (manufactured sand), 5-10mm, 10-20mm, and 20-31.5mm, maximizing profitability.

Green & Intelligent Operation: The entire plant is fully enclosed. High-efficiency dust collectors are installed at all potential dust points, ensuring emissions are far below national standards. The centralized control system allows for "one-button" start-stop and remote monitoring, significantly reducing labor costs and improving production management efficiency.

3. Results & Value Delivered

Since commissioning, the production line has operated smoothly, successfully overcoming the challenges of processing basalt, with all indicators meeting or exceeding expectations.

Exceptional Wear Resistance: The specially configured SUNJEESPOM Cone Crusher and VSI Crusher demonstrated wear resistance that surpassed expectations. The service life of wear parts when processing highly abrasive basalt significantly exceeded the industry average, effectively controlling operational costs and validating the critical equipment selection.

Significant Economic Benefits: The production line consistently operates at a stable output of over 550 TPH, easily achieving an annual capacity of 3 million tons. The high-quality basalt aggregates and sand, known for their strength and durability, became specified materials for high-performance concrete and key projects, commanding premium prices and creating substantial economic benefits for the client.

Outstanding Reliability: The entire line exhibits extremely low failure rates and strong continuous operation capability, guaranteeing a steady supply for the client's downstream operations and enhancing their market reputation and competitiveness.

Environmental Compliance: The plant is clean, with no visible dust or noise pollution, making it a benchmark green mine project in the region. It has passed multiple environmental inspections, enhancing the company's social image.

4. Client Testimonial

Mr. Lin, Production Director of the Group, stated:

"Processing basalt had always been a cost black hole for us until we chose SUNJEESPOM 's solution. Their equipment is truly built for hard rock. The wear life has been a tremendous surprise. From project planning to installation and commissioning, their team demonstrated extreme professionalism. This line not only meets our output targets but also produces the highest quality aggregate products on the market, earning us a golden reputation in the high-end segment. For any future expansion, SUNJEESPOM will undoubtedly be our only choice."