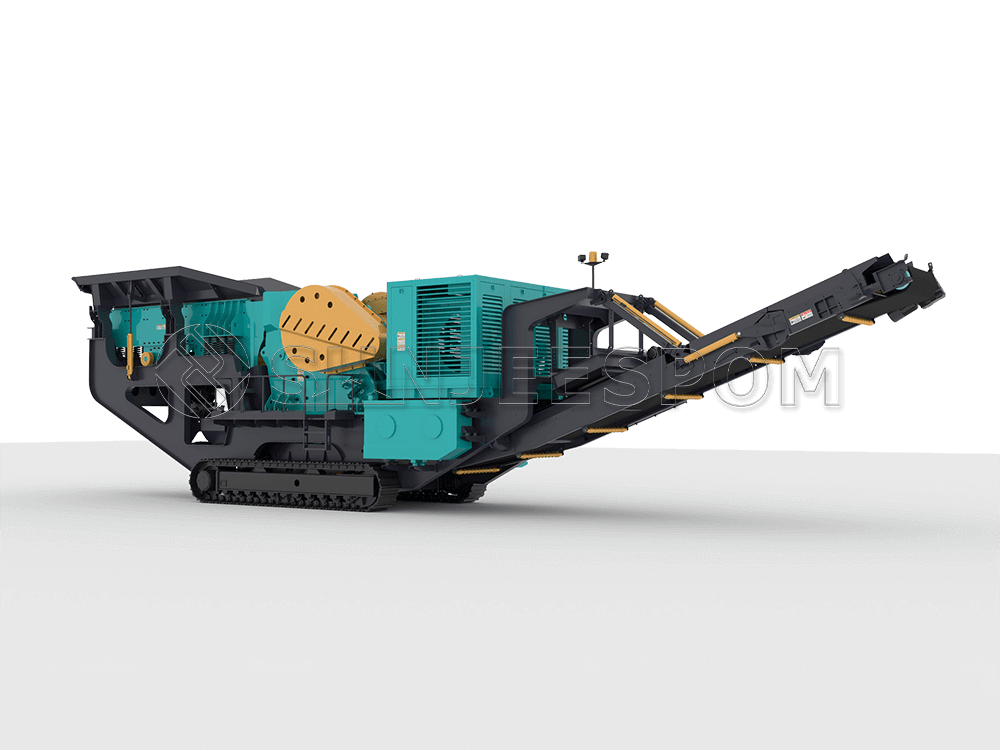

Track-Mounted Mobile Crusher

Feeding Size: 50-80mm

Capacity: 120-625t/h

The Track-mounted Jaw Crusher is a mobile crushing and screening equipment developed by our company by introducing the technology of well-known mining machinery companies and combining with the actual situation in China. The machine uses a hydraulic system to drive the crawler, so as to achieve smooth running, and can adapt to a variety of complex job site conditions. It is widely used in mineral mining, stone mining highways (railways) and bridges, urban construction waste disposal and many other fields.

The material can be evenly transported to the jaw crusher through the feeder. After the primary crushing, the material is sent to the impact crusher through the conveyor for secondary crushing. After crushing, it is output and sent to the vibrating screen. The materials that the conveyor output does not meet the requirements are returned to be crushed again. The whole processing process is a complete production line, which can realize the cyclic crushing of materials and meet the production requirements of customers.

SC series jaw crusher with high efficiency and light weight.

Intelligent control system, customers can remotely control the work or movement of the equipment.

High-performance power systems, Deutz or Cummins engines, to ensure the efficient operation of the equipment.

Multi-power options, the vehicle engine can work independently, can also switch to use external power supply.

The material is evenly transported to the crawler-type hydraulic driven crushing station by the bucket elevator through the feeder. After preliminary crushing by the crusher, a closed-circuit system is formed by a circular vibrating screen to realize the cyclic crushing of the material. output to achieve the purpose of production. The circular vibrating screen can also be removed according to the actual production requirements, and the material can be directly crushed initially, and then cooperated with other crushing equipment to operate.

| Model | TC96 | TC106 | TC116 | TC120 |

| Feeding Machine | ||||

| Equipment | GZD9638 | ZSW1042 | GZD1142 | GZD1248 |

| Motor | 5.5KW*2 | 7.5KW*2 | 7.5KW*2 | 7.5KW*2 |

| Drive Mode | Motor Driven | Motor Driven | Motor Driven | Motor Driven |

| Crusher | ||||

| Equipment | SC96 | SC106 | SC116 | SC120 |

| Max Feeding Size | 550mm | 650mm | 700mm | 800mm |

| Motor | 90KW | 110KW | 132KW | 160KW |

| Drive Mode | Motor Driven | Motor Driven | Motor Driven | Motor Driven |

| Frame | ||||

| Hydraulic Tracked Chassis | 35T | DL385V | DL385V | NS415E |

| Boat Frame | Q345B Welding | Q345B Welding | Q345B Welding | Q345B Welding |

| Main Conveyor | ||||

| Stack Height(mm) | B1000*12.9m | B1000*12m | B1000*12m | B1000*12.9m |

| length x width(mm) | Motor reducer drive 11KW | Motor reducer drive 11KW | Motor reducer drive 11KW | Motor reducer drive 15KW |

| Main Belt Power(kw) | EP300-B1000*5(6.0+1.5) | EP300-B1000*5(6.0+1.5) | EP300-B1000*5(6.0+1.5) | EP300-B1200*5(6.0+1.5) |

| Unearthed belt conveyor | ||||

| Specification | B650*6.8m | B650*6.8m | B650*6m | B650*6.8m |

| Drive Mode | Motor reducer drive 4KW | Motor reducer drive 4KW | Motor reducer drive 4KW | Motor reducer drive 4KW |

| Looped polyester canvas strap | EP200-B650*3(4.5+1.5) | EP200-B650*3(4.5+1.5) | EP200-B650*3(4.5+1.5) | EP200-B650*3(4.5+1.5) |

| Iron remover | ||||

| Specification | RCYQ-13 | RCYQ-13 | RCYQ-13 | RCYQ-13 |

| Drive Mode | Motor reducer drive 3KW | Motor reducer drive 3KW | Motor reducer drive 3KW | Motor reducer drive 3KW |

| Power System | ||||

| Generator Set | 240KW Engine Block | 300KW Engine Block | 300KW Engine Block | 300KW Engine Block |

| Electrical System | ||||

| Electrical control cabinet | Soft start of jaw crusher motor, direct start of other motors, main electrical components Schneider | Soft start of jaw crusher motor, direct start of other motors, main electrical components Schneider | Soft start of jaw crusher motor, direct start of other motors, main electrical components Schneider | Soft start of jaw crusher motor, direct start of other motors, main electrical components Schneider |

| Hydraulic system | ||||

| Silo | Hydraulic Automatic Folding | Hydraulic Automatic Folding | Hydraulic Automatic Folding | Hydraulic Automatic Folding |

| Belt conveyor folding cylinder | Hydraulic Automatic Folding | Hydraulic Automatic Folding | Hydraulic Automatic Folding | Hydraulic Automatic Folding |

| Hydraulic Pumps, Valves, Accessories | Load Sensitive, Electro-hydraulic Proportional Manifold | Load Sensitive, Electro-hydraulic Proportional Manifold | Load Sensitive, Electro-hydraulic Proportional Manifold | Load Sensitive, Electro-hydraulic Proportional Manifold |

Sunjeespom's design is very detailed and takes full account of the ease of use and maintenance. Due to its strong manufacturing capacity, this Track-mounted Jaw Crusher adopts advanced manufacturing technology, which is not only cheap in cost but also highly efficient in use. In the process of communicating with Sunjeespom, I realized their thoughtful service, and many of their Suggestions were in line with the engineering practice, which was of great help to me. In addition, Sunjeespom's non-standard design is very powerful. It can design and manufacture many non-standard equipment according to my needs, which many companies cannot do.

Email is required.